Categories

Latest Updates

As China’s economy continues to grow steadily and the urbanization process is further accelerated, the demand for underground pipelines in China is increasing year by year.In addition, with the increasing awareness of modern civilization and environmental protection, the social problems, traffic problems and environmental pollution caused by underground pipeline construction caused by the excavation of road surface have been paid more and more attention by people.Trenchless underground pipeline construction has the advantages of no pollution to the environment, no traffic impact, short construction period and low comprehensive cost, so it has been widely used in underground pipeline construction.Now trenchless construction technology has many forms, such as shield, pipe jacking, pipe pulling, etc.

1.1 Technological characteristics

1.1.1 Simple construction process, strong operability, easy to organize and implement;Through the site inspection, design the crossing line, connect the drill bit and pipe, the drilling rig is in place, then the construction can begin.

1.1.2 The operation of construction personnel is carried out on the ground, avoiding the influence of bad construction conditions such as deep foundation pit operation and high safety factor;The pipe connection is also carried out on the ground, and the joints are straightforward. After the single section pipe connection is qualified, the one-pull pipe is laid, which improves the quality of pipe connection.

1.1.3 The construction period is short, which greatly shortens the construction period compared with the traditional “pipe digging method”.It does not pollute the environment, affect the traffic, damage to the ground, low cost, significant social and economic benefits.

1.2 Range of application

1.2.1 This technique is a trenchless pipe laying technique, which is suitable for pipe laying across rivers, lakes, buildings and other obstacles as well as municipal underground pipe network construction which is not suitable for excavation.

1.2.2 It is suitable for all types of strata without large pebbles, including water-bearing strata, not for gravel layer, generally for soft soil layer;The pipes are usually steel pipes, PE pipes, PC pipes, etc., with a diameter of 200-1200mm and a maximum length of 1500m.

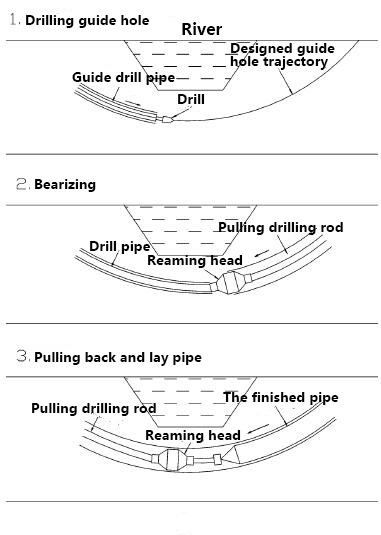

Directional drilling drawn tube technology is the use of directional drilling, drilling and guidance instrument, such as construction equipment, according to the design of borehole trajectory (general approximate curved), using an approximate horizontal directional drilling technology to construction of pilot hole, for the guide hole drill in the crossing obstacle after the other side of the river, road show, unload guide bit put on large diameter of bore hole drilling and reaming drill size smaller than for laying pipeline, then reverse the reaming, pull for laying pipelines into the hole at the same time.Sometimes, according to the capacity of the drilling rig and the diameter of the pipeline to be laid, the pipeline can be pulled back after one or more special reaming. When all the drill pipe is pulled back, the pipe laying will be completed at the same time, as shown in figure 1.

3.1 Project profile

Jinjiang wubian port a sewage pipeline project, the project is located in the downtown area of the town, surrounded by a large number of factories and enterprises, personnel intensive, heavy traffic, and underground pipelines complex.Project construction objective: collect the sewage discharged to wubian port by drainage pipes and culverts on both sides of wubian port river, and transfer it to the sewage plant for treatment and discharge.The pipeline is designed with three pipe diameter (D450, D630 and D00), buried depth (4.1~8.6m), and laying length (2.8km).In order to minimize the impact on the production and life of surrounding enterprises and residents, trenchless pull pipe technology is widely used in the laying of sewage pipelines, which has achieved remarkable economic and social benefits.

3.2 Preliminary survey

Before the implementation of the project, a comprehensive survey should be conducted to master the surface and underground geological conditions of the pull pipe construction area, reasonably design the pipeline direction and the position of entering and leaving the mouth of the hole, and meet the needs of normal production of surrounding enterprises while meeting the needs of the pull pipe construction control.

The contents of the investigation in the construction area of pipe drawing include: first, the exploration of underground pipelines, mainly through the inspection of the original data and underground pipeline detector, to avoid and avoid damage to existing pipelines;Second, geological survey, mainly to the pipeline location of underground dark creek, past backfill, underground facilities and soil quality investigation;Third, the survey of surface obstacles, the surface can meet the navigation equipment through, with the implementation of the basic conditions of control.

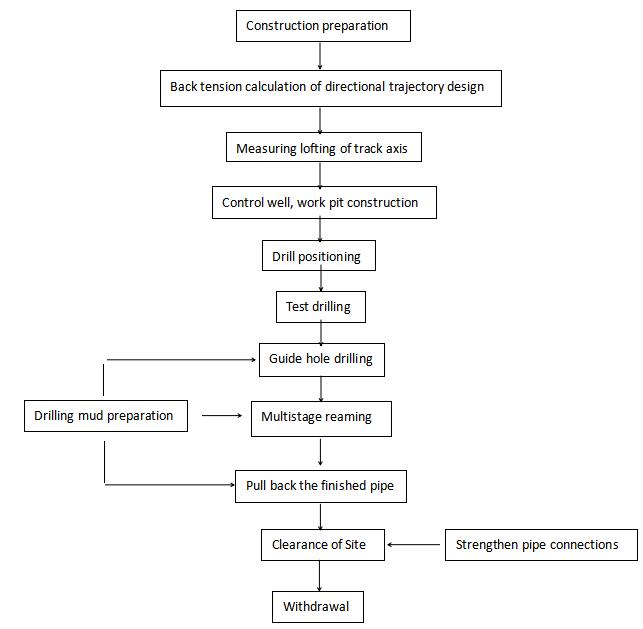

3.3 Drilling construction process (see figure 2)

FIG 2 Construction process flow chart of horizontal directional drilling pull pipe

3.4 Key points of drilling construction technology

3.4.1 Design of guide hole track

1)The guide hole is the busbar and the final pipe hole.Different from other pipelines, sewage drainage pipes have strict requirements on the allowable errors of depth and slope, making construction difficult.Therefore, for busy streets and production areas along the line, the pipeline design should not only consider the actual situation, but also meet the basic conditions of construction, so as to ensure a smaller Angle of entering the soil when the pipeline is drilled.According to the comprehensive design and practical needs, the interval of working well is usually set at the interval of 100-200m.

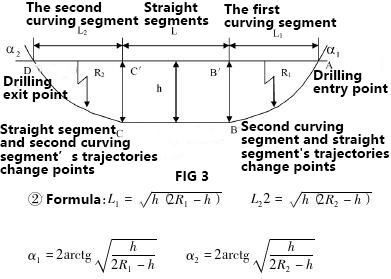

2)Determination of track parameters of guide hole:

①The guide hole trajectory is generally composed of three sections: the first inclined section, the straight section and the second inclined section. The straight section is the actual length of pipeline crossing obstacles; the first inclined section is the transition section where the drill pipe enters the laying position; and the second inclined section is the transition section where the drill pipe is exposed to the surface (see FIG. 3).

In the formula:h-pipe laying;L-horizontal length of directional drill pipe laying;R1-first curving segment’s radius of curvature,It is determined by the bending radius of the drill pipe, generally R1≥1200d(drill pipe diameter mm);R2-first curving segment’s radius of curvature,It is determined by the allowable bending radius of the pipeline to be laid, generally R2≥1200d(diameter mm of the pipeline to be laid);α1-angle od entry;α2-angle of exit.

3.4.2 Backpull calculation: it is a key to calculate backpull in horizontal directional drilling, which is directly related to the selection of drilling rig and pipe.

Estimation formula:F=πLf[γ-dδ1(D-δ1)]+KπDL

In the formula:F-Calculated tension(T);L-Length of passage(m);F-friction coefficient0.1-0.3;D-Production pipe diameter(m);γ-mud density(T/m3);δ1-Wall thickness of main producer tube(m);K-coefficient of viscosity(0.01-0.03)

3.4.3 Directional drilling rig selection (directional drilling rig selection should be based on the calculation value of the above equation 1.5 to 3 times)

This project adopts domestic ddw-350 pipe laying rig and mark 3 guiding instrument.Another power of 45kW non-stop drilling fluid circulation mud mixing system, can quickly prepare drilling mud;Fully functional digital instrument display, with independent hydraulic anchor system.The main technical parameters of the drilling rig: the engine power is 200kW, the maximum thrust/pull is 380kN, the maximum slewing torque is 18kl.m, the output shaft speed is 0-110r/min, the mud system power is 45kW, the mud pump flow is 320L/min, the mud pump pressure is 10MPa, and the Angle is 8°-20°

3.4.4 Selection of pipes

According to the design document, HDPE pipe is selected as the pipe, which has the following characteristics:①High toughness, strong tensile ability, good scratch resistance;②Adopt hot melt butt joint integrated connection, reliable sealing, connection strength is higher than its own strength, suitable for dragging;(3) flexible performance, easy to change the direction of the pipeline in accordance with the construction track;(4) fast crack transmission resistance ability.

3.4.5 Mud preparation

Polymer reinforced mud, made of high quality bentonite mud and a small amount of polymer.The amount of bentonite and polymer in the formulation accounts for about 2% of the mud mass.The same proportion of mud is used in the reaming drag, which has good wall building performance, obvious lubrication and reducing torque, and no collapse.

3.4.6 Guide hole construction

According to the axis of measurement and positioning, operate directional drilling rig to drill horizontally, and use direction controller and other navigation equipment to control the direction and depth of the drill bit on the upper part of the road surface. A circular hole channel with a diameter of about 100mm is formed in strict accordance with the designed axis, and the center line of the channel is the center line of the pipe to be laid.Light pressure and slow rotation are adopted when drilling, and light pressure and fast rotation are adopted when entering straight section to maintain the directivity and stability of drilling tools. Drilling parameters are adjusted timely according to formation changes and drilling depth.During the construction process, pay close attention to whether there are abnormal conditions such as torque, sudden drilling weight and mud leakage during the drilling process, and stop the construction immediately if problems are found.After the guiding hole is completed, check the elevation and orientation of the excavation hole in the working pit and receive the excavation hole to ensure that the hole is formed according to the designed axis.

3.4.7 Expanding the construction

After the completion of the guiding hole, remove the starting rod and the guiding bit, and change back to the expanding bit for backexpanding. During the backexpanding process, the appropriate amount of mud shall be maintained, and the performance parameters of mud shall be tested irregularly, so as to adjust the mud performance index, and reasonably control the drilling speed of backexpanding according to the actual characteristics of the formation, so as to facilitate slag discharge.The reaming shall be completed in 3~5 times, and the corresponding extruding drill bit shall be used in the last backexpanding. If the backexpanding force and backexpanding torque are large, it shall be backexpanding once more to facilitate the formation and stability of the hole wall.According to the characteristics of silt and silt soil in this region, TERA and other diluted powder should be added into the mud mixing system during practical operation. The powder can solidify the tunnel wall, lubricate the drill pipe, and prevent deformation of pipes.In the process of drilling backexpansion, the original construction record should be made in time. If drilling time, axis Angle, torque, jacking force and other abnormal conditions are found, the construction should be stopped immediately and the cause should be found out and the corresponding measures should be taken before the construction.

3.4.8 Pulling back and lay pipe

The connection of HDPE pipe shall be welded in strict accordance with the requirements of electric hot melt construction. The quality of electric hot melt welding shall be checked before pulling back, and the pipe can be towed only after the welding is naturally cooled and qualified.In the process of backtowing pipe, pay close attention to the conditions inside the hole, and the rig operator should pay close attention to the changes of backtowing force and torque of the rig.Towing back should be smooth and smooth, no towing.The pipe should be dragged into the formed hole at one time, avoiding the pause halfway to reduce the drag resistance.

4.1 Design of pipeline track

Different from other pipelines, the gravity flow characteristics of drainage pipeline determine that it must control the smaller slope and elevation error, which puts forward higher requirements for the hole forming control of the cable pipe.In order to ensure the guiding accuracy, the following measures are mainly adopted: first, the feasibility of guiding implementation is fully considered in pipeline design;Second, the appropriate setting of working pit, to ensure the Angle and elevation of soil entry;Third, the measurement frequency is increased to accurately convert the depth of tube position, and the measurement is made every 0.5m.The fourth is to minimize the measurement interference, try to choose in the production gap, traffic vehicles less time to carry out construction.After taking the above measures, the elevation deviation is basically controlled within 50mm, which meets the drainage process requirements.

4.2 Control of pore-forming quality

The main characteristics of hole formation of gravity flow sewage drainage pipe are straight line section with certain slope, small error and no curve section, which is fundamentally different from other pipelines and also the difficulty of construction.In order to meet this requirement, the following measures are mainly taken: first, the excavation of a comparable excavation work well, to design slope or a smaller excavation Angle to control the point of entry;Second, a small number of pipe sections near the entrance and exit are arranged and connected to the inspection well to ensure the pipeline alignment and certain slope of the effective section.

4.3 The subsidence prevention

Another problem encountered in construction is settlement control.Due to the different quality and size of backexpansion head and the influence of poor soil quality, it is inevitable to have clearance outside the pipe. Such clearance is prone to settlement in the pipe section with larger diameter and less buried depth. The main place to prevent and control is the pipe section under the main road.In the construction of pulling pipe, the smaller pipe section below 2m basically does not show obvious decline, and the shallow part has a slight subsidence one to two months later.In order to prevent the occurrence of subsidence when crossing the road, the main measures adopted in the project are: first, the completion of pipe expansion for several times, so as to eliminate the deformation of the soil after the torsion;Secondly, select the cutting head suitable for pipe diameter to minimize the gap;Thirdly, remedial measures should be taken to determine the grouting along with the pipe which must be eliminated but is likely to sink.When such pipe section is pulled back, grouting pipes of 25~30mm are attached on the outside. After the completion of pulling pipes, the outer cracks of the well end pipe are sealed and cement slurry is filled with the grouting machine.This measure is simple and feasible for short distance pipe section and can effectively eliminate the problem of road subsidence.

As a new method of underground pipeline construction, trenchless pipe laying technology has been developed rapidly in China in recent years. With the acceleration of urbanization in China, trenchless pipe laying technology has been more and more favored by people.The development of pipe pulling construction technology opens up new ideas for urban pipeline construction.Through the successful application of engineering examples, this paper has obtained good economic and social benefits, which has certain guiding significance for the construction of similar drainage pipeline projects in the future.